Steel Dynamics to revamp push-pull pickle line with Umlauf Bridles

SDI’s push-pull pickle line in Columbus will be the first in the world to operate with three Umlauf Bridles

Hagen, March 27, 2018

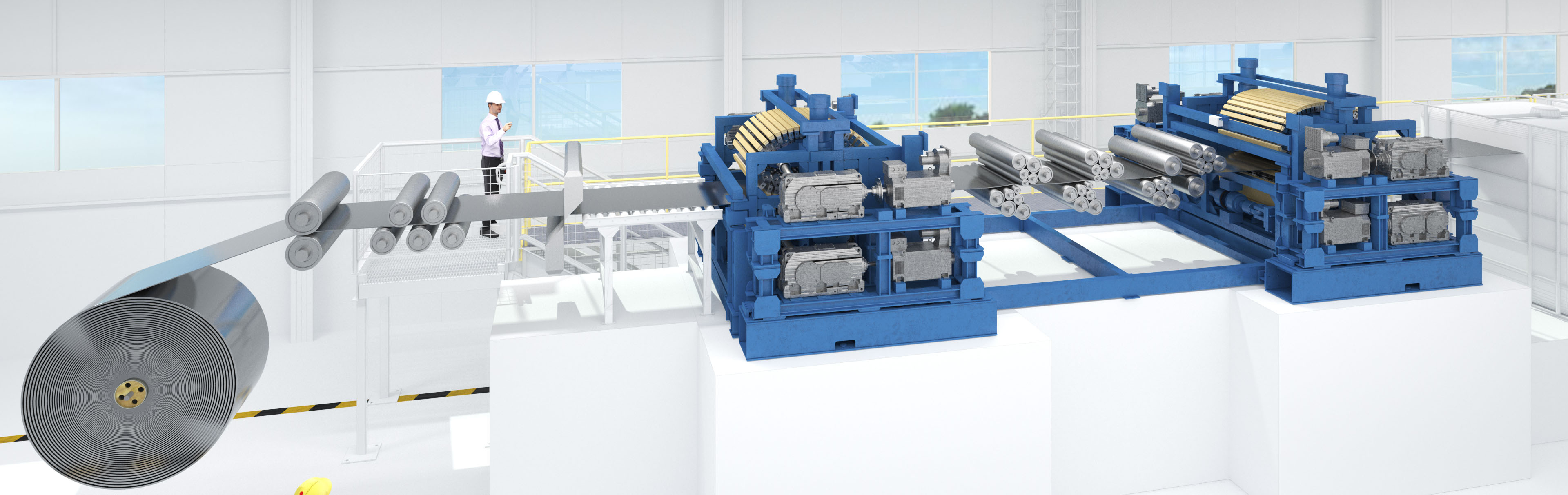

BTU Bridle Technology has received an order from SES Engineering LLC for the construction and delivery of three loop bridles for the modernization of a push-pickling line at Steel Dynamics Flat Roll Group (SDI). This pickling line will be the first in the world to transport the strip exclusively using loop bridles. These bridles generate such high strip tension that even thick and high-strength strips exit the pickling process in a leveled condition. Due to the intensive scale breaking, the modernized pickling line can operate at significantly higher speeds than before.

For the modernization of the push-pickling line at the Columbus, Mississippi plant—managed by SES as the general contractor—SDI places great emphasis on achieving the highest possible strip tension. As a result, the decision was made in favor of BTU’s new Generation 3.0 loop bridles, which, due to their design, apply significantly higher forces to the strip than S-rolls. At the same time, they distribute the strip tension evenly across the strip width.

The first loop bridle, located immediately behind the uncoiler, grips the head of strips up to 13 mm thick and 1,880 mm wide and feeds them into the leveling machine supplied by SES. In combination with the second loop bridle, positioned behind the leveling machine, it applies a strip tension of up to 1,250 kN during stretch leveling. The resulting elongation of 0.5 to 1.0 percent causes the adhering scale to break up intensively, allowing the pickling process to run at speeds of up to 150 m/min.

See also: Technical article in MPT International (2018-3).